The main reasons and treatment methods for burrs in stamped parts

Stamping is a common metal processing method widely used in the manufacturing industry. Its application range is very wide, and it can be used to produce various complex shaped metal parts, such as automotive parts, household appliance accessories, and electricity

Electronic device casing, etc. Stamping processing has the characteristics of high efficiency, precision, and economy, and is therefore widely used in various industries.

Therefore, understanding the generation of stamped parts and their solutions is particularly important.

Stamping burrs are generated during the punching or stamping process, and the main reasons are usually as follows:

1. Excessive material hardness: If high hardness materials are used for stamping processing, it is easy to produce burrs that are difficult to handle during the stamping process.

2. Mold wear: Prolonged or high-frequency use of the mold can cause wear and deformation, resulting in uneven edges and burrs on the stamped parts.

3. Inappropriate cutting angle: If the cutting angle of the punch is not appropriate, it may cause rough edges of the punched parts, resulting in burrs.

4. Improper adjustment: If the punch or mold is not adjusted correctly, it may also cause uneven edges of the stamped parts, resulting in burrs.

5. Insufficient lubrication: The magnitude of friction is also an important factor causing burrs during the stamping process. If lubrication is insufficient, the friction will increase, which may lead to uneven stretching of the material, resulting in burrs.

In response to the above reasons, corresponding measures can be taken to avoid or reduce the occurrence of stamping burrs, such as timely replacement of worn molds, use of materials with appropriate hardness, adjustment of cutting angle, and strengthening lubrication.

So, for the burrs that have already been generated in stamped parts, the following removal methods can be adopted:

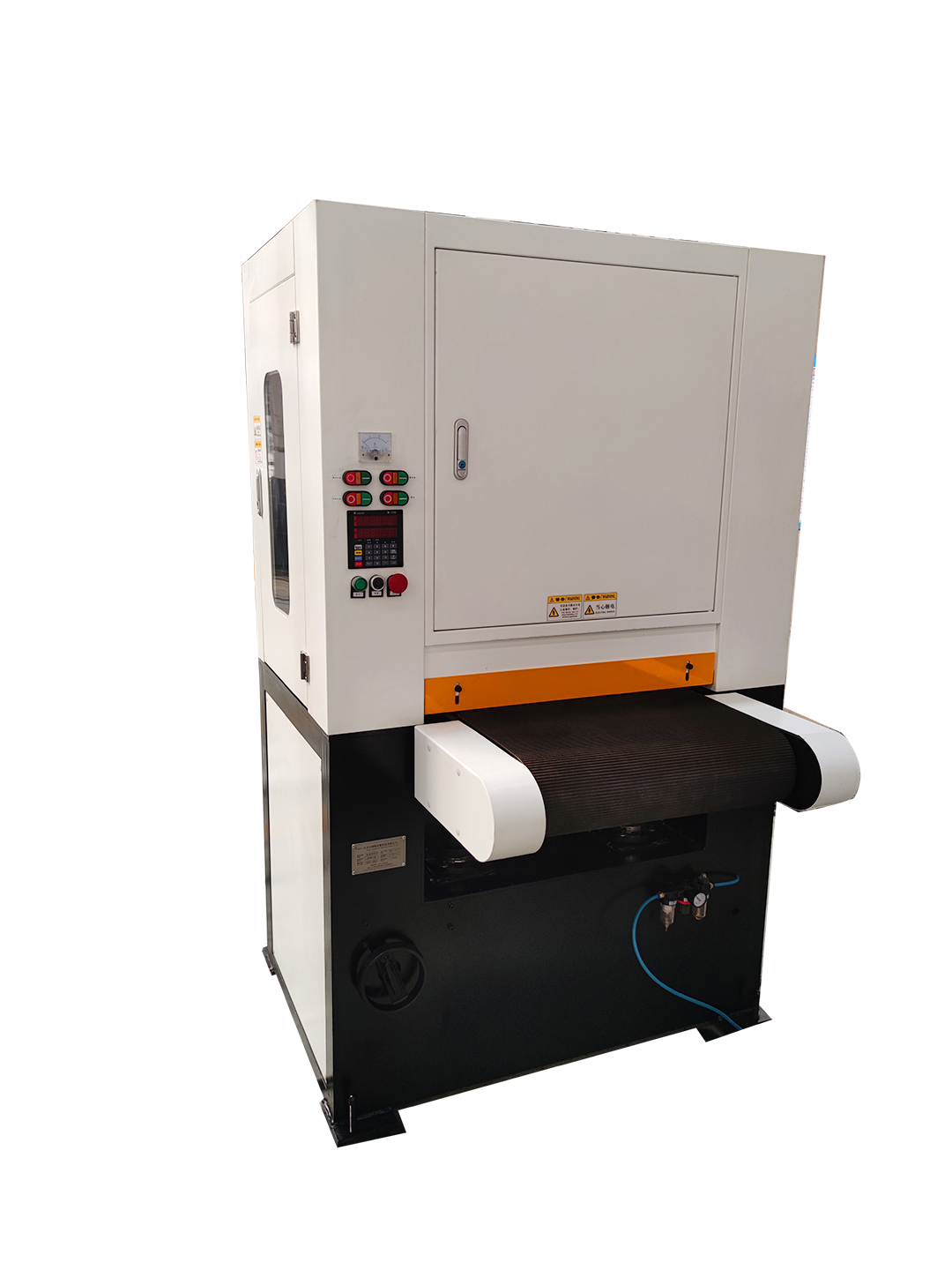

1. Manual deburring: By manually using polishing tools such as sandpaper, grinding machines, etc., the edges of stamped parts are polished and trimmed to achieve a smooth effect.

2. Machine deburring: By using a deburring machine, stamping parts can be deburred with higher efficiency. Dongchang deburring machine can efficiently complete the deburring process of stamping parts, greatly saving labor costs.

3. Chemical deburring: Use chemical etching solution to treat the surface of stamped parts, so that the burrs are filed off and achieve a smooth effect.

It is necessary to choose a suitable deburring plan based on the specific situation to achieve higher production efficiency and product quality.